Having a Blast

For some of us, work can be a blast – literally!

Sometimes, it’s not enough to just build a building or facility – it also needs to be protected against blasts and explosions, so that the people and equipment within can remain safe at all times.

This is where our technologists focusing on protective infrastructures and blast effects come in. A specialised field, protective engineering is all about understanding the effects of threats and hazards, as well as developing solutions to safeguard infrastructure, equipment, systems and people. To facilitate the cross-sharing of knowledge and expertise, the team collaborates extensively with both local and international agencies, including DSO National Laboratories and the Swedish Defence Research Agency.

Threats may come in unconventional forms, and can have devastating effects.

Credit: Swedish Defence Research Agency

While Hollywood makes explosions look sexy, the actual work involved in conducting a trial can really get your hands dirty. However, these trials are necessary as they are one of the best ways for the team to collate data to validate numerical simulations of blast effects on structures and building designs.

One of the trials the team has been conducting locally over the years is the Explosive Testing of Structural Components (ETSC). A platform for large-scale testing of the SAF’s research and technology development programmes, ETSC provides the Weapon Effects, Protection and Operational Analysis communities with a platform to gather valuable data on weapon effects.

Explosive tests like this can be used to ascertain the survivability of mechanical ventilation equipment.

Senior Engineer (Building and Infrastructure) Lim Wen Zhen shared: “These trials really help us better appreciate the sheer power of explosives, and give new meaning to the work we do and the threats we design against.”

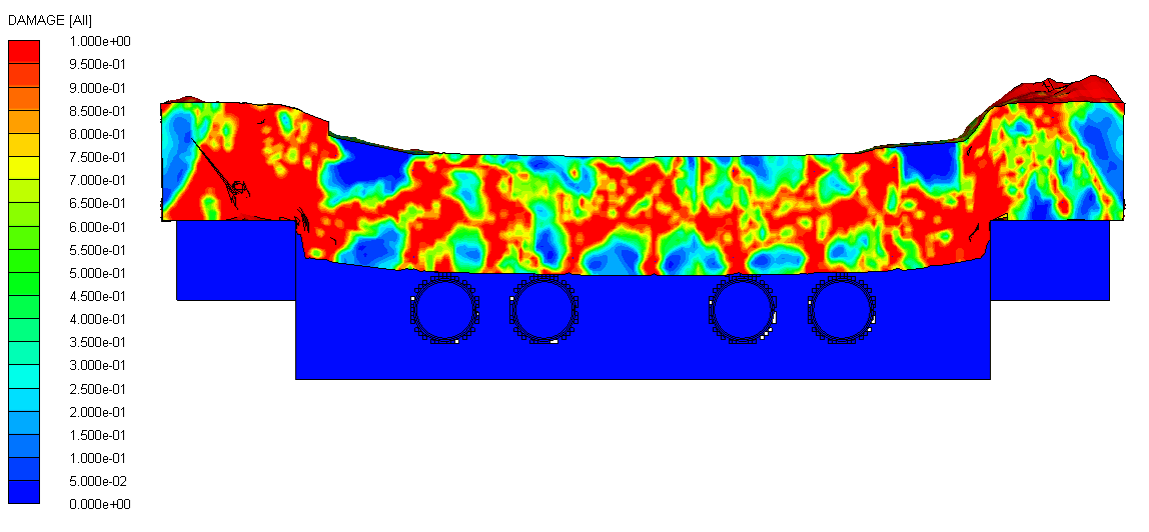

While explosive trials are the best way of assessing the effectiveness of protective designs, another method would be to use numerical simulation to test the designs virtually. Through these simulations, our engineers are able to determine blast loads and derive the performance of protective design solutions.

Currently, numerical simulations and its analysis are almost indispensable in protective design. Engineer (Building and Infrastructure) Germaine Choo explained: “We apply numerical modelling to simulate shock effects on equipment located within buildings due to a blast. It’s exciting to see the simulation come to life and provide crucial data, which helps us optimise the equipment’s shock protection designs.”

Numerical models simulating a pressure loading on a floor slab that has utilities running beneath.

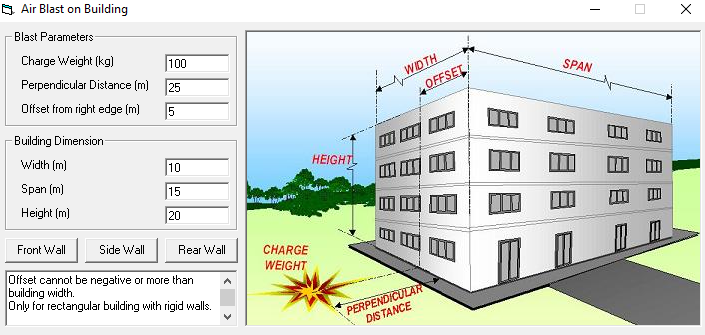

For greater efficiency in blast analysis, the team also designed the capability to develop and use fast-running tools. These tools can analyse blast effects for less complicated scenarios much faster than numerical simulations, and also allow quick modifications of certain parameters to assess changes in blast effects, which shortens the design process extensively.

Such fast-running tools allow the modification of predetermined parameters to generate blast effects instantly.

It was in no small part that through such modelling and testing efforts, our engineers have made the Underground Ammunition Facility – the world’s first large-scale underground containerised facility to be designed and developed within a densely populated and urbanised area – a reality.

Head Engineering (Protective Systems Engineering) Dr Karen Chong, who is one of the team pioneers, said: “Although the work is challenging, it is well worth our efforts. We have helped to validate methodologies used for air blast and debris hazards, and that has formed the basis for the guidelines adopted by the North Atlantic Treaty Organization in its Underground Ammunition Safety Manual.”